Mateusz Berk

Designer and Project & team lead

ABOUT ME:

I like to create, no matter if it is a machine, buggy or furniture. I like to improve and solve problems. I belive in solving problems from the source, in diligent work and incooperations. I am looking for a place where there is work/learn balance. Where I will be able to bring new solutions and learn new solutions

Over 10 global customers

Total projects value: €13,000,000

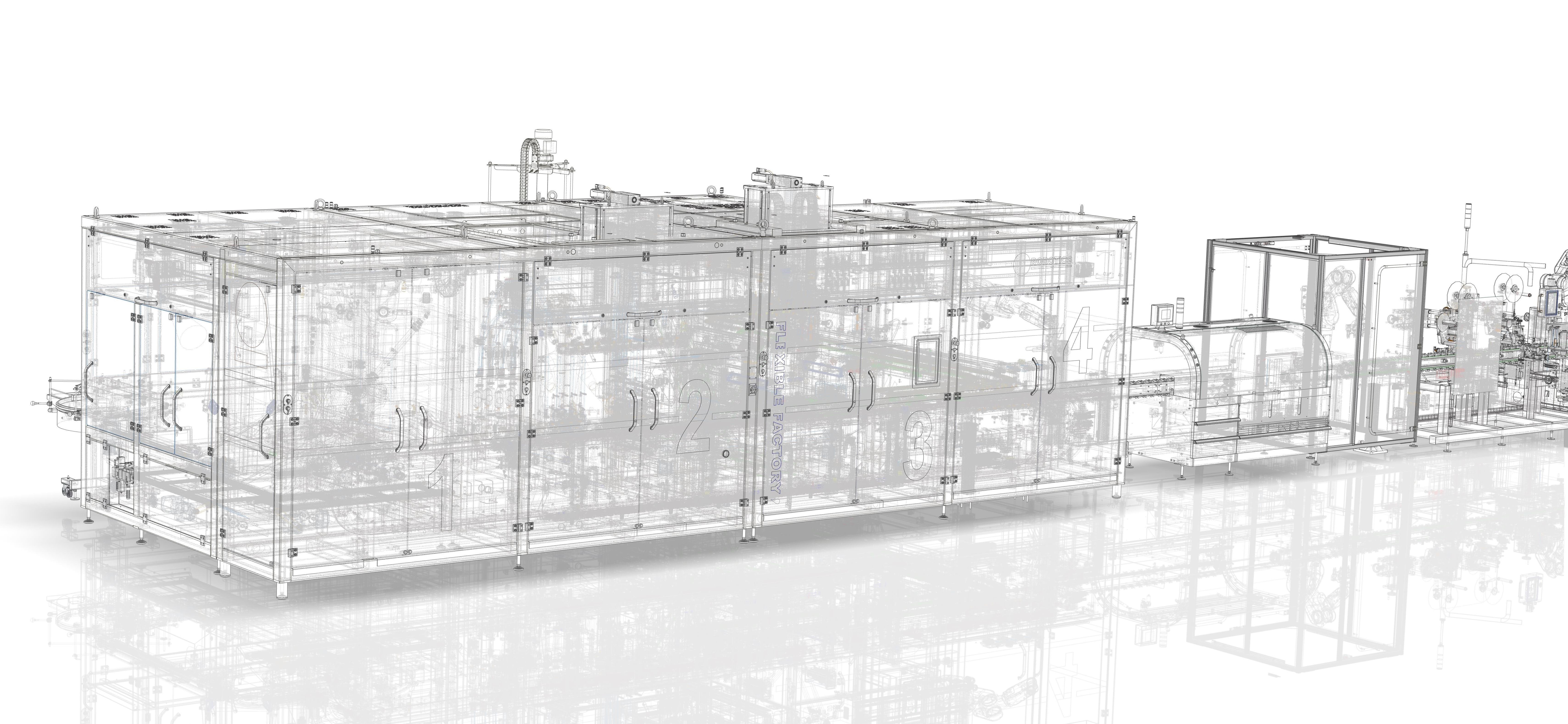

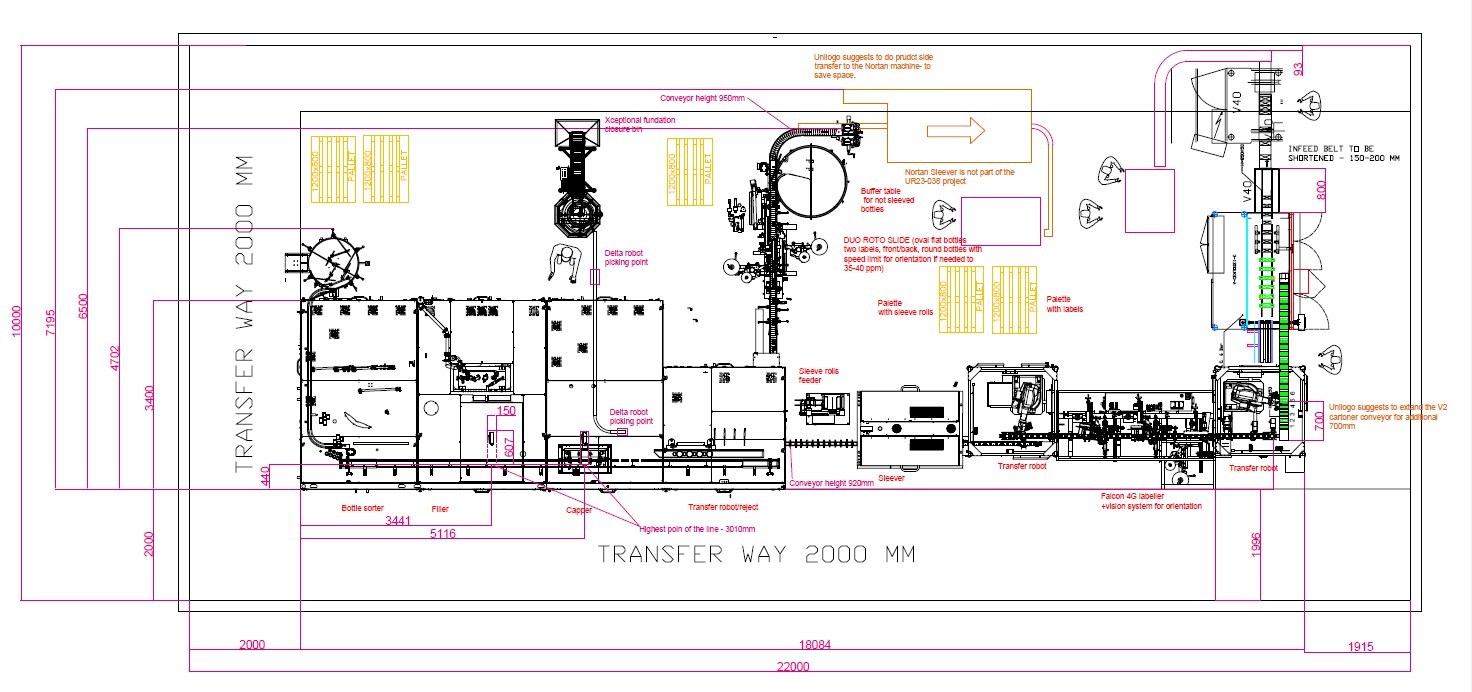

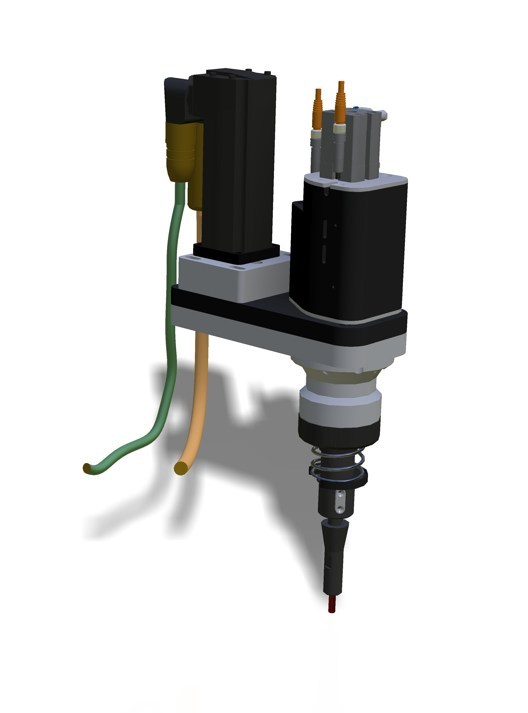

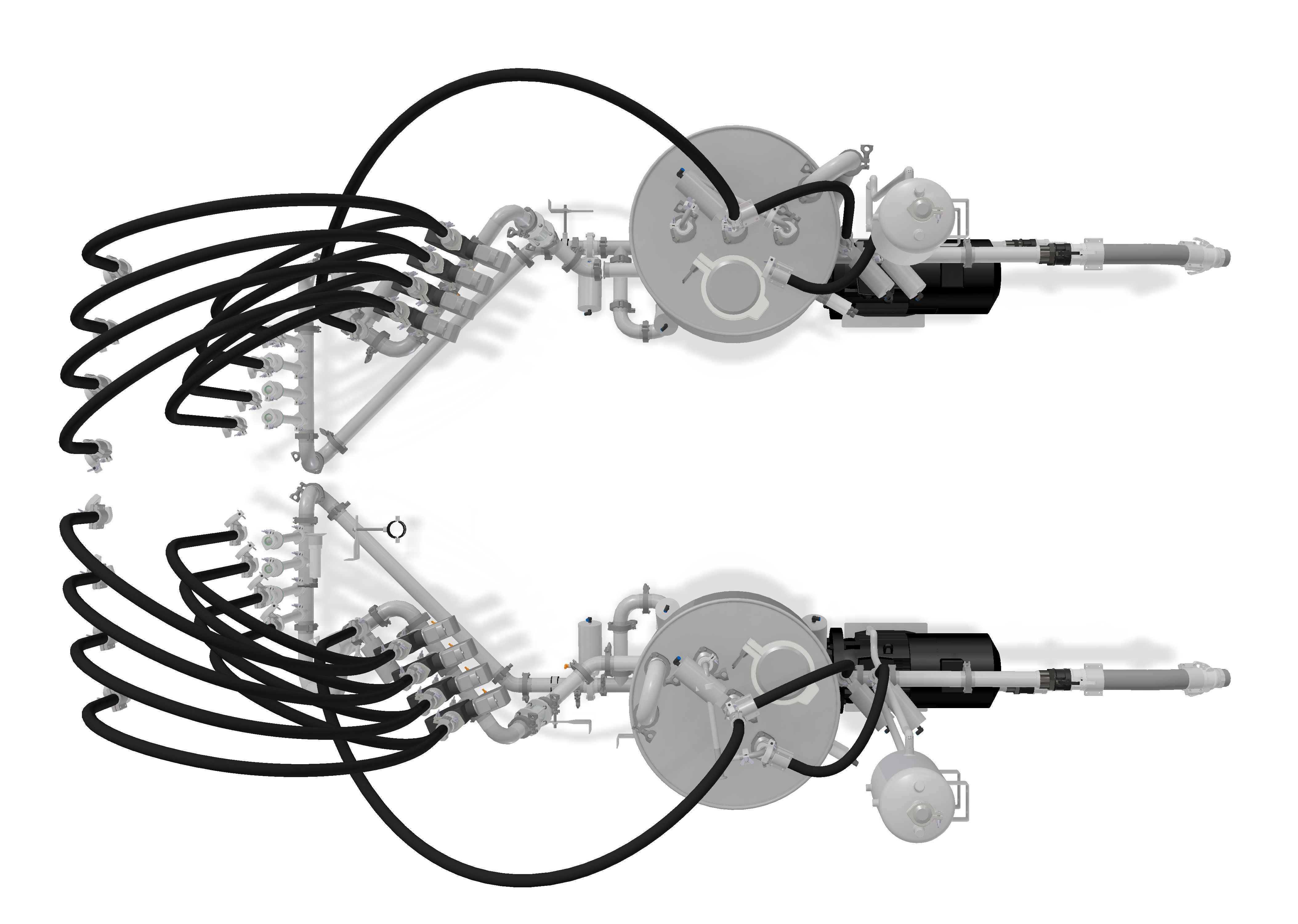

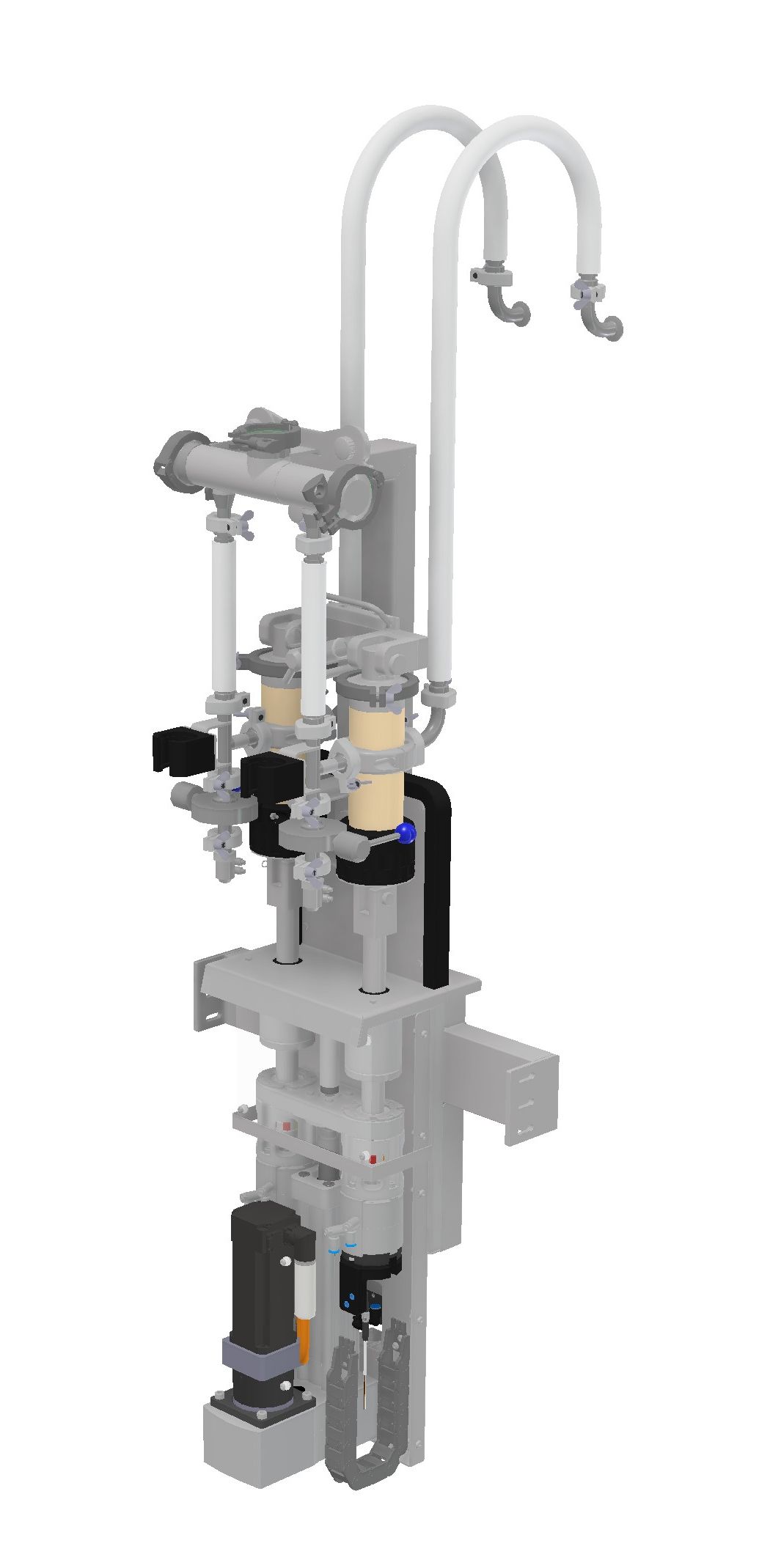

For past 3 years, I have been leading projects involving both individual machines and complete production lines for the cosmetic, household, and industrial cleaning products sector. In each project, I manage a team of 10–14 specialists: designers, machenical and startup technican, programmers. Recent projects typically range from €2–3 million in value and span up to 15 months. My strongest experience lies in primary packaging machinery — from bottle sorting to labeling. Additionally, I have been involved in secondary packaging solutions, including case packers, palletizers, and box labeling systems.